Products Description:

The structure of the cutter head refers to the external shape and internal composition of the cutter head. It belongs to the problem of industrial modeling and involves a wide range. A lot of practice shows that the structure has a great influence on the practical performance of the cutter head. The purpose of improving the structure of the cutter head is to maximize the potential performance of the cutter head, suppress unfavorable conditions, and coordinate the relationship between particle size and life. The improvement of the cutter head structure is mainly based on the characteristics of the carcass, diamond, processing objects, processing equipment, processing technology, etc., and mainly solves two problems: improving the stability of the system; creating good processing conditions.

Improving the stability of the system is mainly to make the wear speed of each part of the cutter head different during use to form a positioning groove, thereby suppressing vibration, reducing the impact force on the diamond, and improving the life of the cutter head.

Specification

|

Introduction |

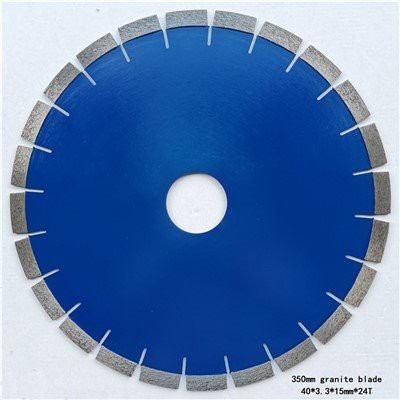

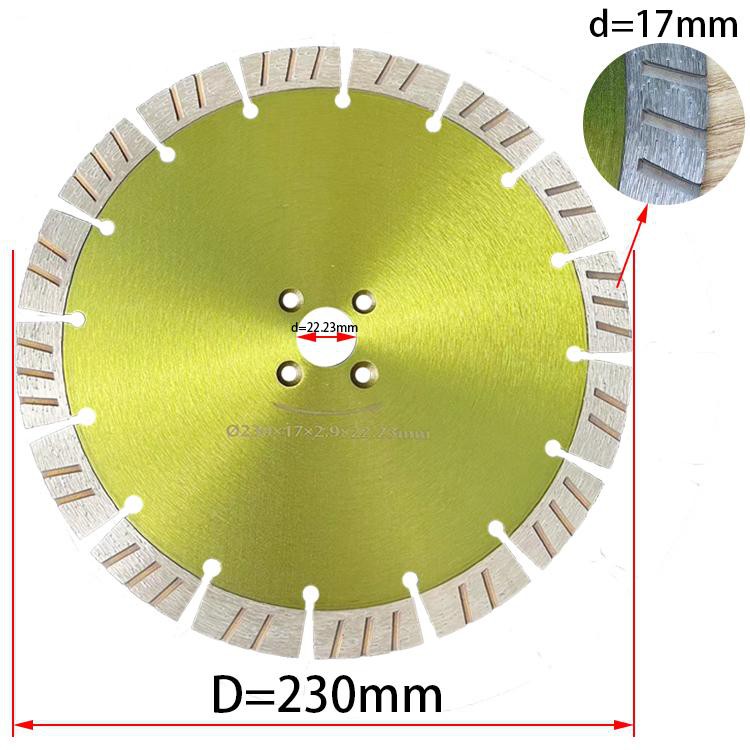

Diamond Cutting Disc (Dry Cutting Blade) |

|

Application |

For cutting Concrete, Block, Brick, Stone, Pavers,marble,granite,tiles,ceramic,wood |

|

Usage |

Dry /wet Cutting |

|

Processing |

Cold pressed |

|

Grade of Blade |

Standard |

|

Size |

4" ( 110mm *20mm, Thickness 2mm, Segment Height: 12mm) |

Main Features

The shape design and structure of the diamond cutter head are mainly to improve the chip capacity, chip removal capacity and cooling and lubrication effect of the diamond segment in the sawing arc area, reduce the friction between the segment and the stone and sawdust, and improve the rock-breaking ability of the diamond , thereby reducing energy consumption and improving the performance of the saw blade. The original diamond circular saw blade segment adopts a uniform rectangular structure. After sawing for a period of time, it is found that the two sides are severely worn, but the middle part is not worn much. The segment will become a convex shape in the cross-sectional direction. The contact area between the working surface of the nodule and the stone increases, and the diamond is easily blunted. In addition, due to the increase of the sawing force, the base of the saw blade is prone to deformation, resulting in uneven thickness and unevenness of the processed plate, and the number of repeated uses of the base is reduced and the service life is shortened. To solve this problem, a layered concave segment is designed, which solves the problems in the sawing of ordinary segments. The characteristics of the concave block are:

(1) The diamond concentration in the outer layer binder is higher than that in the middle layer;

(2) The outer layer binder is more wear-resistant than the middle layer;

(3) The grade of diamond in the outer layer is higher than that in the middle layer;

(4) Make the working length of the middle layer shorter than that of the outer layer through structural design, such as designing a "back" shape, "H" shape or other forms of middle slots;

(5) Add a non-working layer to the multi-layer structure and adjust the width ratio of the working layer and the non-working layer.

Item Detail:

FAQ

Q: When can you ship my order?

A: Normally 15-20days after advanced payment is received. The exact delivery date will be advised after order is confirmed. We will try our best to deliver soonest, if you need them urgently.

Q: How long is the warranty period for machine?

A: one year!

Q: How do you maintain quality stability?

A: We set up a bond file for each client, recording every order he/she placed. We never change the bond of the client's order unless they request or any new technology upcoming.

Hot Tags: discount granite saw blade diamond cutting, China discount granite saw blade diamond cutting manufacturers, suppliers, factory