Main Features

1.High hardness: Stone saw blade is mainly used for cutting various hardness of stone, and the hardness of stone is usually very high, so the stone saw blade also needs to have a high hardness, in order to ensure the cutting effect and life.

2. Wear resistance: The stone saw blade is in contact with the stone surface for a long time when cutting the stone, so it needs to have a high wear resistance to prevent the saw blade from wearing too fast due to long-term use.

3. High strength: Because stone cutting requires great strength and high-speed rotation, the stone saw blade needs to have enough strength to ensure that it will not break or be damaged under high load.

4. Strong adaptability: stone saw blade can be applied to different kinds of stone, and can better play its characteristics when cutting various stones, so as to obtain efficient cutting effect.

5. Low noise, high precision: The general stone saw blade adopts precision processing technology, which can ensure low noise and high precision when cutting, and will not cause too much impact on the surrounding environment.

PS: Other specifications can be customized according to requirement.

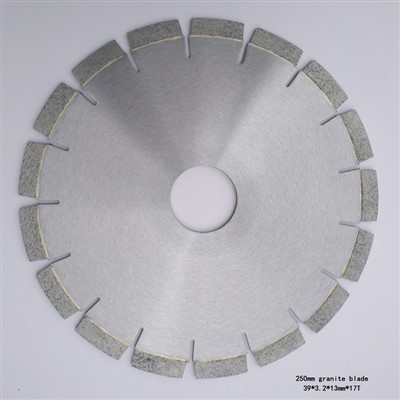

Item Detail:

FAQ

Q:Are you a factory or trading company?

A: We are stone machinery and tools factory also we have professional team of workers.

Q: How can you guarantee the production quality ?

A: We have strictly quality control system in our production process. All products must be double checked during every manufacturing process. Requirement of customers and quality of products will be full guaranteed.

Q: How do you maintain quality stability?

A: We set up a bond file for each client, recording every order he/she placed. We never change the bond of the client's order unless they request or any new technology upcoming.

Products Description

|

Item.No |

Diameter(mm) |

Steel Core Thickness(mm) |

Segment Dimension(mm) |

Segment No. |

|

SGS-SGM300 |

Φ300 |

2.2 |

40×3.2×8(10) |

22 |

|

SGS-SGM350 |

Φ350 |

2.4 |

40×3.4×8(10) |

25 |

|

SGS-SGM400 |

Φ400 |

2.6 |

40×3.6×8(10) |

29 |

|

SGS-SGM450 |

Φ450 |

2.8/3.0 |

40×4.0×8(10) |

32 |

|

SGS-SGM500 |

Φ500 |

3.0/3.2 |

40×4.2×8(10) |

36 |

|

SGS-SGM600 |

Φ600 |

3.6/3.8 |

40×4.8×8(10) |

42 |

|

SGS-SGM700 |

Φ700 |

4 |

40×5.2×8(10) |

42 |

|

SGS-SGM800 |

Φ800 |

4.5 |

40×6.0×8(10) |

46/57 |

|

SGS-SGM900 |

900 |

5.0 |

24×7.5×8(10,12) |

64 |

|

SGS-SGM1000 |

1000 |

5.0 |

24×7.5×8(10,12) |

70 |

|

SGS-SGM1200 |

1200 |

5.5 |

24×8.5×8(10,12) |

80 |

|

SGS-SGM1300 |

1300 |

6.0 |

24×8.5×8(10,12) |

88 |

|

SGS-SGM1400 |

1400 |

6.5 |

24×9.0×8(10,12) |

92 |

|

SGS-SGM1600 |

1600 |

7.2 |

24×9.5×8(10,12) |

108 |

|

SGS-SGM1800 |

1800 |

7.5 |

24×10.0×8(10,12) |

120 |

|

SGS-SGM2000 |

2000 |

8 |

24×10.5×8(10,12) |

128 |

|

SGS-SGM2200 |

2200 |

9 |

24×11.0×8(10,12) |

132 |

|

SGS-SGM2500 |

2500 |

9 |

24×11.0×8(10,12) |

140 |

|

SGS-SGM3000 |

3000 |

9.5 |

24×12.0×8(10,12) |

160 |

Hot Tags: grinder steel cutting disc, China grinder steel cutting disc manufacturers, suppliers, factory, cut off wheel for grinder, angle grinder cutting discs, 230mm stone grinding disc, grinder blade for concrete, angle grinder disc for porcelain tile, concrete cutting wheel