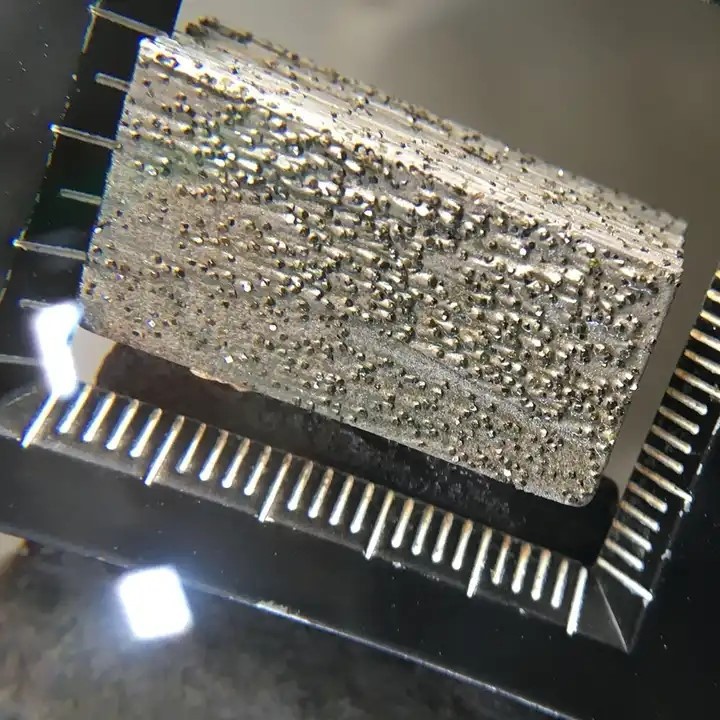

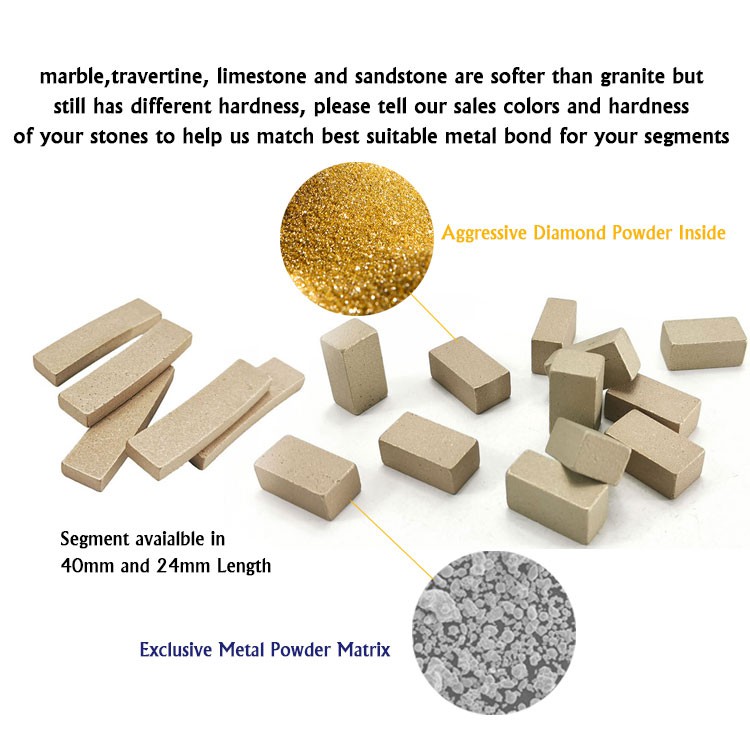

Diamond Segment Stone Cutter Tools

Description:

Diamond segment is also called diamond agglomerate, saw tooth, etc. It is a kind of diamond tool product that is often used in the sawing process. Diamond segment is generally not used alone, but can be welded to the saw blade base to form a diamond circular saw blade. It can also be welded to the gang saw substrate to form a gang saw, and it can also be welded to metal iron discs, bowl mills, drill bits and other substrates to form diamond grinding discs, diamond bowl mills, diamond drill bits and other products. It can be said that in stone processing, most of the grinding, drilling and cutting processes are completed by diamond cutter heads. Without diamond cutter heads, many processes cannot continue normally, so diamond cutter heads are the most important in the entire stone industry. basic tools and materials.

FAQ

Q: Can I get a lower price if I order large quantities ?

A: Of course, we will give you a specific offer.

Q: What is your competitiveness ?

A: We are the biggest stone processing machines manufacturer in China. Our machine has good price with best quality. Each machine has its own relevant patent, long lifetime, high production capacity and accuracy. Also, we could appoint our engineer to come overseas to help the customer if machine got problem.

Q: How can you guarantee the production quality ?

A: We have strictly quality control system in our production process. All products must be double checked during every manufacturing process. Requirement of customers and quality of products will be full guaranteed.

Specification:

*250-800mm

| Diameter(mm) | Segment Size(mm) | Segment NO.(pcs/set) | Welding Method | Structure | ||

| Length | Width | Height | ||||

| 250 | 40 | 2.5 | 8/10 | 18 |

Silver Welding or Laser Welding |

Multi-Layer or No-Layer

|

| 300 | 40 | 3.2 | 8/10 | 21 | ||

| 350 | 40 | 3.2/3.4 | 8/10 | 24/25 | ||

| 400 | 40 | 3.6 | 8/10 | 28 | ||

| 450 | 40 | 4.0 | 8/10 | 32 | ||

| 500 | 40 | 4.2 | 8/10 | 36 | ||

| 550 | 40 | 4.4 | 8/10 | 38 | ||

| 600 | 40 | 4.6 | 8/10 | 42 | ||

| 700 | 40 | 5.0 | 8/10 | 50 | ||

| 725 | 40 | 5.5 | 8/10 | 50 | ||

| 800 | 40 | 5.2 | 8/10 | 46 | ||

*900-3500mm

| Diameter(mm) | Segment Dimension(mm) | Segment No. | Welding Method | Structure | ||

| Length | Width | Height | ||||

| 900 | 24 | 7.0/6.5 | 10/12/15/20 | 64 |

Silver Welding or Laser Welding |

Multi-Layer or No-Layer |

| 1000 | 24 | 7.0/6.5 | 10/12/15/20 | 70 | ||

| 1100 | 24 | 7.4/6.8 | 12/15/20 | 74 | ||

| 1200 | 24 | 7.5/7.0 | 12/15/20 | 80 | ||

| 1300 | 24 | 8.0/7.5 | 12/15/20 | 88 | ||

| 1350 | 24 | 8.4/7.7 | 12/15/20 | 88 | ||

| 1400 | 24 | 8.5/8.0 | 12/15/20 | 96 | ||

| 1600 | 24 | 9.0/8.7/8.4 | 12/15/20 | 108 | ||

| 1700 | 24 | 9.4/8.9/8.4 | 12/15/20 | 112 | ||

| 1800 | 24 | 9.5/9.0 | 12/15/20 | 120 | ||

| 2000 | 24 | 10.5/9.5 | 12/15/20 | 128 | ||

| 2200 | 24 | 11.5/10.5 | 12/15/20 | 132/136 | ||

| 2500 | 24 | 12/11.5/11 | 15/20/25/30 | 140 | ||

| 2700 | 24 | 12/11.5/11 | 15/20/25/30 | 140 | ||

| 3000 | 24 | 12.5/12/11.5 | 15/20/25/30 | 160 | ||

| 3500 | 24 | 13/12.5/12 | 15/20/25/30 | 180 | ||

Hot Tags: diamond segment manufacturer cutter, China diamond segment manufacturer cutter manufacturers, suppliers, factory