for Diamond Wire Saw Blades.

Introduction:

Diamond wire saw blades are advanced cutting tools that utilize industrial diamonds to slice through various materials with high precision and accuracy. These blades are widely used in the construction and manufacturing industries to cut through hard materials like granite, marble, and concrete, among others. Diamond wire saw blades have revolutionized the way we cut hard materials, offering efficient, effective, and cost-saving solutions to an array of industries.

In this article, we will delve into the features and benefits of diamond wire saw blades and offer insights on how to choose the right blade for your needs.

Features:

1. Diamond wire saw blades are durable:

The wire saw blades are made of high-quality stainless steel and diamonds, making them highly durable and long-lasting. The industrial diamonds on the blades are of high quality, which ensures that the blade retains its sharpness over time.

2. Cutting speed:

Diamond wire saw blades can slice through hard materials at high speed and with high precision. This ensures a faster and cleaner cut compared to traditional cutting tools like saw blades and grinders.

3. Cut accuracy:

The blades are designed to cut through materials with high accuracy, ensuring that the end-product is of high quality. Diamond wire saw blades cut through hard materials cleanly without causing chipping or cracking.

4. Versatility:

Diamond wire saw blades can be used to cut through a wide range of materials, including natural stone, ceramic, glass, and even metals. They are widely used in construction, manufacturing, and other industries where hard materials need to be cut precisely.

Benefits:

1. Cost savings:

Diamond wire saw blades are highly efficient, saving on time and labor. They can cut through materials faster than traditional cutting tools, which minimizes labor costs for manufacturers and contractors.

2. Precision:

Diamond wire saw blades offer high precision, which ensures that the cuts made are of high quality. Costly errors, such as chipping, cracking, and breaking of materials during the cutting process, are eliminated.

3. Improved quality:

Using diamond wire saw blades enhances the quality of the end-product. This improves customer satisfaction and leads to repeat business.

4. Safe:

Diamond wire saw blades are safer to use compared to traditional cutting tools like grinders and saw blades. They create less dust and noise, enhancing the safety of the work environment.

5. Time-saving:

Diamond wire saw blades save time since they cut through materials faster, making them perfect for large-scale construction and manufacturing projects.

Factors to consider when choosing a diamond wire saw blade:

1. Material to cut:

Different diamond wire saw blades are designed to cut through specific materials. It is essential to consider the material you need to cut before choosing the right blade.

2. Grit size:

Grit size refers to the size of the diamond particles on the blade. Blades with larger diamond particles have a coarser grit and are ideal for cutting through hard materials like granite and marble. Whereas blades with smaller diamond particles are designed for softer materials.

3. Bond type:

The bond type determines the blade's ability to retain the industrial diamonds. Soft bonds work well with hard materials like marble and granite, while hard bonds are ideal for softer materials like limestone and sandstone.

4. Blade thickness:

The blade thickness determines the blade's ability to withstand wear and tear during cutting. The thicker the blade, the more durable it is.

Conclusion:

Diamond wire saw blades are a game-changer in the construction and manufacturing industries. They offer cost-effective, efficient, and high-precision cutting solutions for a wide range of materials. When choosing a diamond wire saw blade, it is essential to consider the material you need to cut, the grit size, bond type, and blade thickness. Choosing the right blade ensures that the work is done efficiently, accurately, and safely, which leads to improved quality and customer satisfaction.

Product Description:

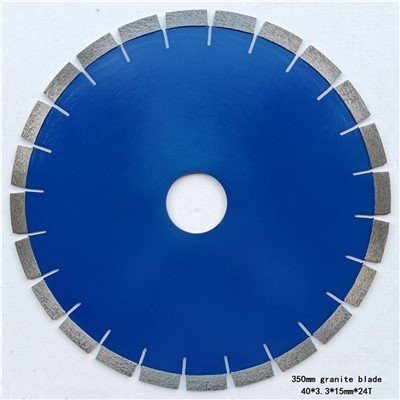

Application | 1. For Stone Quarry, Block Squaring&Chamfering, Profiling Cutting 2. For Cutting Reinforced Concrete |

Diameter Of Wire Saw | 7.2mm, 8.0mm, 8.5mm, 9.0mm, 11.0mm, 11.5mm |

Technology | Sintered, Electroplated, Vaccum Brazed |

Coating Fix Injection | Plastic, Rubber, Spring, Rubber+Spring, Plastic+Spring |

Beads/Meter | 40/37/33/28/26pcs |

Attention | 1. Checking the saw regularly and adjust timely. 2. Checking the pearl abrade regularly, Avoid the eccentric wear 3. Checking the joint regularly and adjust timely. 4. The tension of ropes is 250-300kg(Φ4-5mm ropes) 5. Water supply is around 15-25L/min |

Feature | 1. Very less breakage ratio when using therefore increase the working lifetime. 2. Automatic production ensures stable quality performance. 3. Safe, high efficiency and environment protecting. |

Production Picture

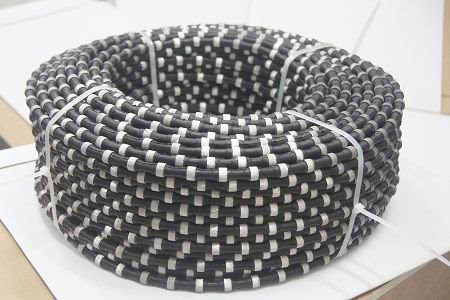

1. Diamond Wire Saw For Quarry:

We recommend rubber wire, it can protect the wire saw rope very well and increase the wire's strength.

The rubber has good temperature resistance, and it can be used when water is not enough.

Strong flexibility can reduce the cut-in-one-side problem.

2. Diamond Wire Saw For Block Dressing:

We recommend plastic wire, it can be used to dissect marble granite.

It can cut accurately with small inter-space.

It can cut the block with the thickness of 2.3M

3. Diamond Wire Saw For Profiling:

We recommend plastic wire for shaping operations provides a huge range of possibilities

It makes smooth surface, and accurate sizes with small inter-space.

Columns and elements for the building industry can be produced in much more economic way.

4. Diamond Wire Saw For Reinforce Concrete Cutting:

5. Diamond Multi-Wire Saw For Slab Cutting:

Diamond multi-cutting wire saws are suitable for cutting the different kinds of large granite slabs

Remark: modern gang saw can produce in a month 3000 to 4000 square meters of slabs of 2cm thickness

The multi-wire can produce 5000 to 6000 square meters of slabs cut at any thickness between 1 to 5 cm.

Advantage:

1. Connected by best quality Rubber, Spring, Plastic

2. 100%Germany made steel cable

3. Beads produced with high percent of cobalts

4. High grade of diamonds

5. Pre-Sharpened beads, easy starting

Why Choose us?

1. We are leading manufacturer in diamond machinery

2. Rich experience in Global market, export to more than 60 countries.

3. 100% QC inspection Before shipment

4. Keep researching and developing the latest technology

5. Reply within 24 hours.

Why choose us?

- Our Saw Blade products are made to the highest international standards of quality and durability.

- By promoting the automation of our production units, the company has reduced the procedures for employees to operate the equipment manually and reduced the probability of accidents. All our staff warmly welcome new and old friends from home and abroad to visit our company for guidance. High quality products and services will be the cornerstone of our sincere cooperation and common development.

- For all of your Saw Blade needs, count on our Chinese factory to deliver top-quality products and outstanding customer service.

- Diamond Wire Saw Blade is the source of power for the development of human society. Every progress of human civilization is accompanied by changes and replacements. Safety, efficiency, economy, and wisdom are always the eternal topics of mankind.

- When it comes to Saw Blade products, our Chinese factory is the perfect choice for those who value quality, reliability, and affordability.

- Our company will improve productivity as our most important economic work focus.

- Our Saw Blade factory employs the latest technology and best practices to ensure that our products are of the highest possible quality.

- We attach importance to every opportunity to serve you, welcome you to consult with us, and look forward to creating a win-win situation with you.

- We are a renowned Saw Blade supplier and manufacturer, recognized for our commitment to quality and reliability.

- We take the market demand as our guideline, take economy, practicality and efficiency as our benchmark, introduce and learn the latest technology to continuously improve and perfect our Diamond Wire Saw Blade.

Hot Tags: diamond wire saw blade, China diamond wire saw blade manufacturers, suppliers, factory, melamine cutting blade, brick saw blade, saw brush blade, 12 inch chainsaw blade, 8 inch diamond blade, glass tile cutting blade