Products Description:

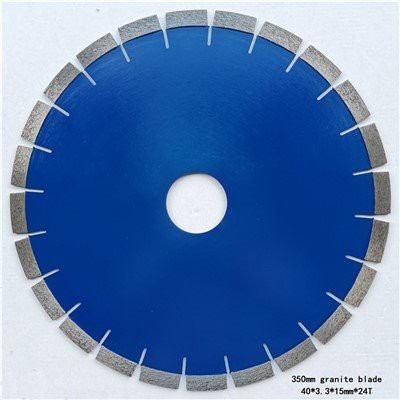

The segment consists of three parts: the diamond working area, the concave transition layer and the weld layer. Single Grain

size (fine grain) diamond is used in the diamond working area to cut granite (soft and medium hard) slabs and artificial stone

The slab. The inner concave transition layer does not contain diamonds and the sector is divided into two working areas.

Similar to the short tooth segment structure, it can improve the sharpness of the saw blade. In addition, the intermediate

transition layer can play a role of cushioning and chip removal during the cutting process, and reduce the frictional resistance between the abrasive

side of the cut block and stone, which can improve the sharpness of the saw blade. No diamond inside the welding layer

Ensure the welding strength and cutting safety between the saw blade and the base material.

Product size:

|

Item.No |

Diameter(mm) |

Steel Core Thickness(mm) |

Segment Dimension(mm) |

Segment No. |

|

SGD-SGN300 |

Φ300 |

2.2 |

40×3.2×10(12,15) |

21 |

|

SGD-SGN350 |

Φ350 |

2.2/2.4 |

40×3.4×10(12,15) |

24 |

|

SGD-SGN400 |

Φ400 |

2.6 |

40×3.6×10(12,15,20) |

28 |

|

SGD-SGN450 |

Φ450 |

2.8/3.0 |

40×4.0×10(12,15,20) |

32 |

|

SGD-SGN500 |

Φ500 |

3.0/3.2 |

40×4.2×10(12,15,20) |

36 |

|

SGD-SGN600 |

Φ600 |

3.6/3.8 |

40×4.8×10(12,15,20) |

36/42 |

|

SGD-SGN700 |

Φ700 |

4 |

40×5.2×10(12,15,20) |

42 |

|

SGD-SGN800 |

Φ800 |

4.5 |

40×6.0×10(12,15,20) |

46 |

|

SGD-SGN900 |

900 |

5.0 |

24×7.0/6.4×12(15,20) |

64 |

|

SGD-SGN1000 |

1000 |

5.0 |

24×7.0/6.4×12(15,20) |

70 |

|

SGD-SGN1200 |

1200 |

5.5 |

24×8.0/7.4×12(15,20) |

80 |

|

SGD-SGN1300 |

1300 |

6.0 |

24×8.4/7.8×12(15,20) |

88 |

|

SGD-SGN1400 |

1400 |

6.5 |

24×8.4/7.8×12(15,20) |

92 |

|

SGD-SGN1600 |

1600 |

7.2 |

24×9.2/8.4×12(15,20) |

108 |

|

SGD-SGN1800 |

1800 |

7.5 |

24×10.0/9.0×12(15,20) |

120 |

|

SGD-SGN2000 |

2000 |

8 |

24×10.5/9.5×15(20,25) |

128 |

|

SGD-SGN2200 |

2200 |

9 |

24×11.0/10.0×15(20,25) |

132 |

|

SGD-SGN2500 |

2500 |

9 |

24×11.5/10.5×15(20,25) |

140 |

|

SGD-SGN3000 |

3000 |

9.5 |

24×12.5/13.5×20(25,30) |

160 |

|

SGD-SGN3500 |

3500 |

9.5 |

24×13.5/14.5×20(25,30) |

180 |

Advantage

1. High hardness: Diamond is the hardest known substance, so diamond saw blades have very high hardness and wear resistance, which can keep sharp and durable when cutting hard materials.

2. High precision: Diamond saw blades cut with very high precision, which can meet the requirements of high precision processing.

3. High efficiency: diamond saw blade cutting speed is fast, can complete a large number of cutting tasks in a relatively short time.

4. Long life: diamond saw blades have very good wear resistance, and can be used for a long time without frequent replacement.

5. Can be widely used: Diamond saw blades can be used to process various hard materials, such as stone, ceramics, glass, metal, etc., with good adaptability.

6. Environmental protection and safety: diamond saw blades do not produce dust and harmful gas during processing, which is safe for both the environment and the operator.

Main Features

1. High hardness: stone saw blade is mainly used for cutting various hardness of stone, and the hardness of stone is usually very high, so the stone saw blade also needs to have high hardness, to ensure the cutting effect and life.

2. Wear resistance: Stone saw blade is in contact with stone surface for a long time when cutting stone, so it needs to have high wear resistance to prevent the saw blade from wearing too fast due to long-term use.

3. High strength: Because stone cutting requires great strength and high-speed rotation, the stone saw blade needs to have enough strength to ensure that it will not break or be damaged under high load.

4. Strong adaptability: stone saw blade can be applied to different kinds of stone, when cutting all kinds of stone can better play its characteristics, so as to obtain efficient cutting effect.

5. Low noise and high precision: general stone saw blade adopts precision machining technology, which can ensure low noise and high precision when cutting, and will not cause too much impact on the surrounding environment.

PS: Other specifications can be customized according to requirement.

Item Detail:

|

Product Name |

Metal cutting blade for grinder |

|

Material |

Blade Material: Diamond Grit diamond and metal |

|

Process |

HOT PRESS, High Frequency Welded, Laser welded, |

|

Blade Type |

Diamond Segmented Blade |

|

Application |

For cutting granite, marble stone and contrece block, tile,hard brick, paver bricks |

|

Package |

Paper box, white paper box and color paper box |

|

Slot type |

Key slot |

|

Lead time |

15~30days |

|

MOQ |

20pcs |

|

payment |

T/T |

FAQ

1.Are you a manufacturer or trading company?

We are a 26 years manufacturer.

2.How to prove your quality?

We use E6 diamond,Dipea steel wire, passed ISO9001 and SGS,strict quality control and skilled workers.

3.What should I do if the products is not suitable for the market?

Giving us the detailed report first,then we analyze the reason,try to find the solutions.

If it is our problems,we will give you new products.

4.Do you provide free samples?

Small sample is welcomed.But,usually we don't provide free samples.

5.Can you provide OEM/OEM services?

It is ok.

Products Description

|

Item.No |

Diameter(mm) |

Steel Core Thickness(mm) |

Segment Dimension(mm) |

Segment No. |

|

SGS-SGM300 |

Φ300 |

2.2 |

40×3.2×8(10) |

22 |

|

SGS-SGM350 |

Φ350 |

2.4 |

40×3.4×8(10) |

25 |

|

SGS-SGM400 |

Φ400 |

2.6 |

40×3.6×8(10) |

29 |

|

SGS-SGM450 |

Φ450 |

2.8/3.0 |

40×4.0×8(10) |

32 |

|

SGS-SGM500 |

Φ500 |

3.0/3.2 |

40×4.2×8(10) |

36 |

|

SGS-SGM600 |

Φ600 |

3.6/3.8 |

40×4.8×8(10) |

42 |

|

SGS-SGM700 |

Φ700 |

4 |

40×5.2×8(10) |

42 |

|

SGS-SGM800 |

Φ800 |

4.5 |

40×6.0×8(10) |

46/57 |

|

SGS-SGM900 |

900 |

5.0 |

24×7.5×8(10,12) |

64 |

|

SGS-SGM1000 |

1000 |

5.0 |

24×7.5×8(10,12) |

70 |

|

SGS-SGM1200 |

1200 |

5.5 |

24×8.5×8(10,12) |

80 |

|

SGS-SGM1300 |

1300 |

6.0 |

24×8.5×8(10,12) |

88 |

|

SGS-SGM1400 |

1400 |

6.5 |

24×9.0×8(10,12) |

92 |

|

SGS-SGM1600 |

1600 |

7.2 |

24×9.5×8(10,12) |

108 |

|

SGS-SGM1800 |

1800 |

7.5 |

24×10.0×8(10,12) |

120 |

|

SGS-SGM2000 |

2000 |

8 |

24×10.5×8(10,12) |

128 |

|

SGS-SGM2200 |

2200 |

9 |

24×11.0×8(10,12) |

132 |

|

SGS-SGM2500 |

2500 |

9 |

24×11.0×8(10,12) |

140 |

|

SGS-SGM3000 |

3000 |

9.5 |

24×12.0×8(10,12) |

160 |

Hot Tags: metal cutting blade for grinder, China metal cutting blade for grinder manufacturers, suppliers, factory