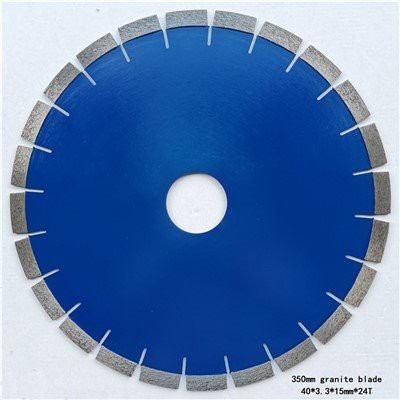

Description:

Diamond saw blade is a professional tool, widely used in construction, stone processing, concrete, ceramics and other industries of cutting, grinding, dressing. Diamond saw blade has the characteristics of high wear resistance, high cutting efficiency, long service life and high precision. According to different application scenarios and needs, diamond saw blades can be divided into dry type and wet type, as well as drilling, flat cut, corrugated and other different shapes and sizes. Common specifications are 4 ", 5 ", 6 ", 7 ", 8 "and so on. Users should choose different specifications and models of diamond saw blades according to their specific needs when using.

Features:

1. Diamond saw blade: Diamond saw blade is equipped with diamond blade, which is much tougher than traditional cutting blade. They can easily cut through hard materials such as concrete, asphalt and stone.

2. Water cooling: Many diamond cutting saws use a water cooling mechanism to keep the blade cool and reduce friction, thus achieving faster and more accurate cutting.

3. Variable speed: Some saw models allow users to adjust the speed of the blade to match the type of material being cut. This helps extend the life of the blade and ensures clean, accurate cutting.

4. Dust collection: diamond cutting saw will produce a lot of dust, harmful to the health of the user, causing confusion. Many saws are equipped with dust collection devices that remove debris during the cutting process.

5. Power source: Diamond cutting saws usually have electric or gas driven models. Electric saws are generally quieter and easier to use, while air saws are more powerful and can last longer without needing to be recharged.

Dafon profoessional factory offer Diamond grinding wheel for ceramic or granite tile :

1. Very good wear resistance, long service life

2. High grinding efficiency, high hardness

3. Minimum damage resistance, low wear

4. Good chemical stability, relatively stable without deformation

5. Can be customized according to the needs of individual design

6. Heat resistance and wear resistance, durable and long cutting time

Technical data:

|

Blade diameter/mm |

Segment length/mm |

Segment thickness/mm |

Segment height/mm |

Blade teeth/pcs |

|

300 |

40 |

2.8/3.0 |

8/10/12/15/20 |

21/22 |

|

350 |

40 |

3.0/3.2 |

8/10/12/15/20 |

24/25 |

|

400 |

40 |

3.4/3.6 |

8/10/12/15/20 |

28/29 |

|

450 |

40 |

3.8/4.2 |

8/10/12/15/20 |

32 |

|

500 |

40 |

4.0/4.2 |

8/10/12/15/20 |

36 |

|

550 |

40 |

4.6/4.8 |

8/10/12/15/20 |

40 |

|

600 |

40 |

4.6/4.8 |

8/10/12/15/20 |

42 |

FAQ

Q: Are you a factory or trading company?

A: We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q: What kinds of stone machine do you have?

A: We have all kinds of stone machine, such as stone edging machine, mining machine,spitting machine, polishing machine, block cutter machine and so on

Q: Do you have more stone machines?

A: Yes, we can produce all series of stone processing machines with competitive price and high quality. Infrared Bridge Saw Stone Tile Cutting Machine is one of our machines.

Hot Tags: Thin Cutting Wheels Diamond Turbo Saw Metal Cutting Blade, China Thin Cutting Wheels Diamond Turbo Saw Metal Cutting Blade manufacturers, suppliers, factory