Specification

|

Application |

Diameter (mm) |

Fixing |

Beads/m |

Cutting Material |

Line Speed(m/s) |

Cutting Speed(㎡/h) |

Life (㎡/m) |

|

Stone Processing |

Φ6.4 Φ7.3 Φ9.0 Φ10.5 Φ11.5 |

Plastic |

37PCS/M |

Soft |

26~32 |

10~30 |

26~32 |

|

Mid-hard |

26~30 |

8~25 |

26~30 |

||||

|

Hard |

25~28 |

7~20 |

25~28 |

||||

|

Quarry |

Φ11.0 Φ11.5 Φ12.5 |

Rubber Rubber+Spring |

40PCS/M |

Soft |

28~33 |

20~30 |

25~35 |

|

Mid-hard |

26~33 |

15~25 |

15~25 |

||||

|

Hard |

24~30 |

10~15 |

10~15 |

Additional Features and Advantages:

Features:

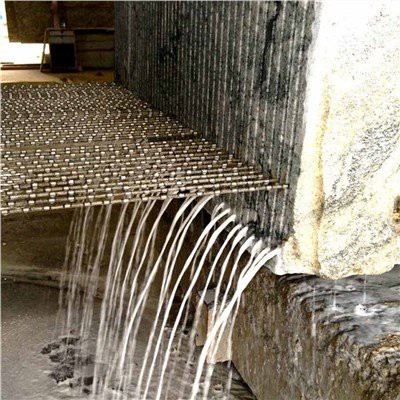

Multi-Material Cutting: The Cutting Wire Saw is engineered to cut through a variety of materials, including metals, stone, ceramics, and more, offering a versatile solution for diverse industries.

Minimal Material Waste: Precision cutting minimizes material wastage, optimizing resource utilization and reducing overall production costs.

Ease of Operation: The user-friendly design of the Cutting Wire Saw makes it easy to operate, even for those with limited experience, enhancing overall workflow efficiency.

Adaptable Cutting Parameters: Advanced control mechanisms allow users to customize cutting parameters, adjusting for specific materials and project requirements.

Swift Setup: The Cutting Wire Saw offers quick and hassle-free setup, enabling users to start cutting operations promptly.

Advantages:

Precision and Clean Cuts: The wire saw's precision ensures clean and accurate cuts, reducing the need for additional finishing work and enhancing final product quality.

Versatility Across Industries: Whether it's construction, manufacturing, or crafts, the Cutting Wire Saw adapts to various industries, making it a valuable asset for different applications.

Reduced Downtime: Efficient cutting mechanisms and adaptable parameters reduce operational time, leading to enhanced productivity and reduced downtime.

Cost-Effective: The minimal material waste, improved efficiency, and adaptability of the wire saw contribute to overall cost savings in production and material usage.

Enhanced Safety: Safety features integrated into the design prioritize operator safety, reducing risks and creating a safer working environment.

Quality Control: Precise cutting ensures consistent quality across finished products, meeting industry standards and customer expectations.

Innovation in Cutting Technology: By utilizing the advanced capabilities of the Cutting Wire Saw, businesses can demonstrate innovation and remain at the forefront of cutting technology.

Elevate your cutting processes with the precision, versatility, and efficiency of our Cutting Wire Saw. This cutting-edge tool offers unparalleled advantages, optimizing your workflow, reducing costs, and ensuring high-quality results across various materials and industries.

Item Detail

|

Product: |

cutting wire saw |

|

Brand name: |

Dafon |

|

Application: |

For mining, cutting slabs, cutting shaped stones, wall separation cutting concrete |

|

Material: |

Rubber Wire Saw Rope |

|

Delivery time: |

10-15days |

|

MOQ: |

10m |

|

Place of origin: |

Quanzhou, China |

|

Process: |

Sintered Beads |

|

OEM: |

Accepted |

|

Warranty: |

1year |

FAQ

1. What types of materials can the Cutting Wire Saw cut through?

The Cutting Wire Saw is designed to cut through a wide range of materials, including metals, stone, ceramics, plastics, and more, making it suitable for various industrial applications.

2. How does the wire saw ensure precision cutting?

The Cutting Wire Saw employs advanced technology to achieve precision cutting, resulting in clean and accurate cuts across different materials.

3. Can I adjust the cutting parameters for specific materials?

Yes, the Cutting Wire Saw features advanced control mechanisms that allow users to adjust cutting parameters, optimizing the cutting process for different materials and applications.

4. Is the wire saw suitable for beginners?

Absolutely, the Cutting Wire Saw is designed for user-friendly operation, making it accessible to both experienced professionals and beginners.

5. Does the wire saw come with safety features?

Yes, the wire saw incorporates safety features such as overload protection and emergency stop mechanisms to prioritize operator safety during cutting operations.

6. Can I use the wire saw for both small and large-scale cutting tasks?

Yes, the Cutting Wire Saw is versatile and can be used for a wide range of cutting tasks, from small-scale precision work to larger industrial operations.

7. How does the wire saw compare to traditional cutting methods?

The Cutting Wire Saw offers precision, versatility, and efficiency that often surpass traditional cutting methods, resulting in reduced material waste and improved overall performance.

8. Can the wire saw be integrated into automated systems?

Depending on the model, the Cutting Wire Saw may be compatible with automated systems, providing seamless integration into production lines.

9. What maintenance is required for optimal performance?

Regular maintenance checks and adherence to provided guidelines are recommended to ensure the Cutting Wire Saw's consistent and reliable performance.

10. How does the wire saw contribute to cost savings in cutting operations?

The Cutting Wire Saw's precision, adaptability, and efficiency reduce material wastage, operational time, and overall costs, contributing to substantial savings.

For additional inquiries or specific concerns, please feel free to contact our customer support team at yux@dafonstonemachine.com.

Hot Tags: cutting wire saw, China cutting wire saw manufacturers, suppliers, factory, quarry wire saw, diamond wire cutting steel, concrete wire saw, diamond wire for granite, wire saw for concrete, steel cutting wire saw