Specification

|

Application |

Diameter (mm) |

Fixing |

Beads/m |

Cutting Material |

Line Speed(m/s) |

Cutting Speed(㎡/h) |

Life (㎡/m) |

|

Stone Processing |

Φ6.4 Φ7.3 Φ9.0 Φ10.5 Φ11.5 |

Plastic |

37PCS/M |

Soft |

26~32 |

10~30 |

26~32 |

|

Mid-hard |

26~30 |

8~25 |

26~30 |

||||

|

Hard |

25~28 |

7~20 |

25~28 |

||||

|

Quarry |

Φ11.0 Φ11.5 Φ12.5 |

Rubber Rubber+Spring |

40PCS/M |

Soft |

28~33 |

20~30 |

25~35 |

|

Mid-hard |

26~33 |

15~25 |

15~25 |

||||

|

Hard |

24~30 |

10~15 |

10~15 |

Additional Features and Advantages to Attract Customers:

Features:

Customizable Cutting: The Quarry Wire Saw offers customizable cutting parameters, allowing adjustments for different stone types, sizes, and quarry conditions, ensuring optimal results.

High Cutting Speed: Engineered for efficiency, this wire saw delivers high cutting speed, reducing operational time and boosting productivity in quarrying tasks.

Minimal Noise and Vibration: Designed with noise and vibration reduction mechanisms, the Quarry Wire Saw provides a more comfortable and quieter working environment for operators.

Remote Operation Capability: Some models of the Quarry Wire Saw offer remote operation functionality, enabling operators to control the cutting process from a safe distance.

Ease of Maintenance: User-friendly maintenance features simplify upkeep, minimizing downtime and ensuring consistent performance throughout the quarrying operations.

Advantages:

Cost Efficiency: The Quarry Wire Saw's precision cutting minimizes material wastage, saving costs in both stone extraction and processing, resulting in higher overall profitability.

Improved Resource Utilization: By achieving accurate cuts, this wire saw optimizes the use of extracted stone, reducing the need for secondary shaping and enhancing resource utilization.

Enhanced Safety Standards: The inclusion of safety features and remote operation options prioritize operator safety, reducing potential risks associated with the quarrying process.

Environmental Sustainability: The reduced waste and resource-efficient approach of the Quarry Wire Saw align with sustainable practices, minimizing the environmental impact of quarrying.

Competitive Edge: Utilizing the advanced technology of the Quarry Wire Saw can give your quarry a competitive advantage, as it enhances productivity, quality, and safety compared to traditional methods.

Versatility Across Stone Types: Whether it's granite, marble, limestone, or other stone types, the Quarry Wire Saw's adaptability ensures consistent performance across a variety of materials.

Elevate your stone extraction operations with the advanced capabilities and advantages of our Quarry Wire Saw. As you explore the potential of this cutting-edge tool, you'll experience increased efficiency, reduced costs, and enhanced safety, all contributing to a more successful and sustainable quarrying venture.

Item Detail

|

Product: |

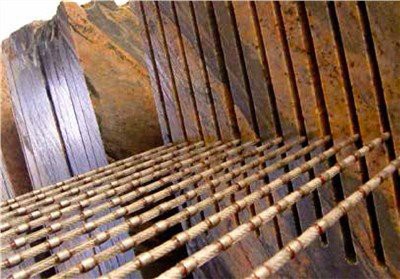

quarry wire saw |

|

Brand name: |

Dafon |

|

Application: |

For mining, cutting slabs, cutting shaped stones, wall separation cutting concrete |

|

Material: |

Rubber Wire Saw Rope |

|

Delivery time: |

10-15days |

|

MOQ: |

10m |

|

Place of origin: |

Quanzhou, China |

|

Process: |

Sintered Beads |

|

OEM: |

Accepted |

|

Warranty: |

1year |

FAQ

1. What types of stones can the Quarry Wire Saw extract?

The Quarry Wire Saw is designed to extract a wide range of stones, including granite, marble, limestone, and more, making it versatile for various quarrying operations.

2. How does the wire saw's customizable cutting parameters work?

The Quarry Wire Saw's customizable parameters allow operators to adjust cutting speed and depth according to specific stone types and sizes, optimizing extraction efficiency.

3. Does the wire saw require specialized training for operation?

Operating the Quarry Wire Saw requires training to ensure safe and efficient use. Proper training enhances operator competence and safety during the quarrying process.

4. How can the wire saw reduce waste during stone extraction?

The wire saw's precision cutting minimizes waste by achieving accurate cuts, optimizing stone utilization and reducing the need for secondary shaping.

5. Are remote operation models available for the wire saw?

Yes, certain models of the Quarry Wire Saw offer remote operation functionality, allowing operators to control the cutting process from a distance for added safety.

6. What maintenance is required for the wire saw's consistent performance?

Regular maintenance checks and adherence to the provided maintenance guidelines are essential to ensure the Quarry Wire Saw's consistent and reliable performance.

7. How does the wire saw contribute to environmental sustainability?

The wire saw's reduced waste and resource-efficient approach align with sustainable practices, minimizing the environmental impact of stone extraction.

8. Can the wire saw be used for irregularly shaped stones?

Yes, the adaptability of the Quarry Wire Saw allows it to be used for extracting irregularly shaped stones, provided they fit within the cutting parameters of the machine.

9. What safety features does the wire saw have?

The Quarry Wire Saw includes safety features such as overload protection and emergency stop mechanisms, prioritizing operator safety during the extraction process.

10. How can using the Quarry Wire Saw benefit my quarry's competitiveness?

By enhancing productivity, minimizing waste, and improving safety, the Quarry Wire Saw can give your quarry a competitive edge, resulting in increased efficiency and profitability.

Hot Tags: quarry wire saw, China quarry wire saw manufacturers, suppliers, factory, diamond wire rock saw, steel cutting wire saw, diamond coated wire saw, diamond wire saw blade, diamond wire for granite cutting, wire saw wire