Specification

|

Application |

Diameter (mm) |

Fixing |

Beads/m |

Cutting Material |

Line Speed(m/s) |

Cutting Speed(㎡/h) |

Life (㎡/m) |

|

Stone Processing |

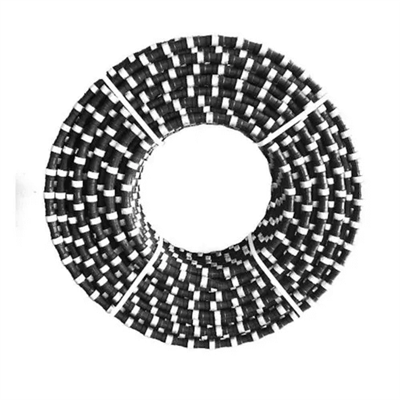

Φ6.4 Φ7.3 Φ9.0 Φ10.5 Φ11.5 |

Plastic |

37PCS/M |

Soft |

26~32 |

10~30 |

26~32 |

|

Mid-hard |

26~30 |

8~25 |

26~30 |

||||

|

Hard |

25~28 |

7~20 |

25~28 |

||||

|

Quarry |

Φ11.0 Φ11.5 Φ12.5 |

Rubber Rubber+Spring |

40PCS/M |

Soft |

28~33 |

20~30 |

25~35 |

|

Mid-hard |

26~33 |

15~25 |

15~25 |

||||

|

Hard |

24~30 |

10~15 |

10~15 |

The Diamond Wire Cutting for Reinforced Concrete boasts several key features and advantages:

1. Precision and Efficiency: This technology offers exceptional precision in cutting, allowing for intricate and accurate shaping of reinforced concrete structures. Its efficient operation speeds up tasks compared to traditional methods.

2. Strength of Diamond Infusion: The diamond-infused wires used in the cutting process provide remarkable strength and durability, enabling the cutting through reinforced concrete with ease.

3. Reduced Vibrations and Noise: Unlike conventional techniques that often generate high levels of vibrations and noise, this method significantly minimizes such disturbances, making it suitable for urban environments and sensitive surroundings.

4. Minimal Damage: The precise cutting action of diamond wires minimizes the risk of unintended damage to adjacent structures or materials, ensuring a cleaner and safer work environment.

5. Environmental Friendliness: By decreasing dust and emissions during the cutting process, the technology aligns with sustainable practices, contributing to a greener and healthier work environment.

6. Versatility: Whether for controlled demolitions, renovations, or intricate construction tasks, Diamond Wire Cutting is versatile enough to handle a wide range of applications.

7. Enhanced Safety: The reduced vibrations, minimal dust, and improved control offered by this technology enhance overall safety conditions for workers and the surrounding area.

8. Time and Labor Savings: Its efficiency and precision can lead to substantial time and labor savings, boosting project timelines and reducing costs.

9. Future-focused: This technology represents a significant step forward in the evolution of concrete manipulation methods, showcasing a glimpse into the future of construction and demolition techniques.

Embrace the innovation and experience a superior way to handle reinforced concrete with the Diamond Wire Cutting solution.

Item Detail

|

Product: |

diamond wire cutting reinforced concrete |

|

Brand name: |

Dafon |

|

Application: |

For mining, cutting slabs, cutting shaped stones, wall separation cutting concrete |

|

Material: |

Rubber Wire Saw Rope |

|

Delivery time: |

10-15days |

|

MOQ: |

10m |

|

Place of origin: |

Quanzhou, China |

|

Process: |

Sintered Beads |

|

OEM: |

Accepted |

|

Warranty: |

1year |

FAQ

Q1: What is Diamond Wire Cutting for Reinforced Concrete?

A1: Diamond Wire Cutting for Reinforced Concrete is a cutting-edge technology that utilizes diamond-infused wires to precisely and efficiently cut through reinforced concrete structures with minimal noise, vibration, and environmental impact.

Q2: How does Diamond Wire Cutting work?

A2: The process involves threading a high-strength wire infused with diamond particles around the concrete section to be cut. The wire is then systematically tensioned and pulled through the concrete, effectively slicing it with remarkable precision.

Q3: What are the advantages of using Diamond Wire Cutting over traditional methods?

A3: Diamond Wire Cutting offers precision, reduced vibrations, minimal noise, and decreased dust and emissions. It causes less damage to adjacent structures and materials, is environmentally friendly, and can save time and labor due to its efficiency.

Q4: What types of projects is Diamond Wire Cutting suitable for?

A4: Diamond Wire Cutting is versatile and applicable to a wide range of projects, including controlled demolitions, renovations, structural modifications, and intricate construction tasks that involve reinforced concrete.

Q5: Is Diamond Wire Cutting safe for workers and the surrounding environment?

A5: Yes, Diamond Wire Cutting is designed with safety in mind. The reduced vibrations and controlled cutting process enhance safety for workers, while the minimal dust and emissions contribute to a safer and healthier work environment.

Q6: Does Diamond Wire Cutting technology have any environmental benefits?

A6: Absolutely. The technology generates fewer emissions and dust compared to traditional methods, making it environmentally friendly. It aligns with sustainable practices and contributes to a cleaner atmosphere on construction sites.

Q7: Can Diamond Wire Cutting be used in urban areas with noise restrictions?

A7: Yes, Diamond Wire Cutting is well-suited for urban environments due to its minimal noise and vibration output. It complies with noise restrictions and allows work to proceed without causing disturbances to neighboring areas.

Q8: Can Diamond Wire Cutting handle complex shapes and angles in reinforced concrete?

A8: Yes, the precision and flexibility of Diamond Wire Cutting allow it to handle complex shapes and angles with ease. Its accuracy ensures that intricate cuts can be made without compromising structural integrity.

Q9: Does Diamond Wire Cutting require specialized operators?

A9: Yes, while the technology is user-friendly, skilled operators with training in handling the equipment are recommended to ensure optimal results and safety during the cutting process.

Q10: How does Diamond Wire Cutting contribute to project cost savings?

A10: The efficiency of Diamond Wire Cutting can lead to reduced labor costs and project timelines. Its precision also reduces the need for costly repairs or rework caused by inaccuracies in cutting.

Experience the future of reinforced concrete manipulation with Diamond Wire Cutting technology. Contact us for more information and to explore its benefits for your projects.

Hot Tags: diamond wire cutting reinforced concrete, China diamond wire cutting reinforced concrete manufacturers, suppliers, factory, diamond wire saws for stone, diamond multi wire saw, wire saw cutting granite, stone cutting wire saw, stone wire saw, diamond wire for concrete