Why Choose Us ?

Customized services

We understand that each customer has unique manufacturing needs. That's why we offer customization options, to cater to your specific requirements.

Advanced equipment

A machine, tool or instrument designed with advanced technology and functionality to perform highly specific tasks with greater precision, efficiency and reliability.

High quality

Our products are *manufactured* to very high standards, using the finest materials and manufacturing processe.

Competitive price

We offer a higher-quality product or service at an equivalent price. As a result, we have a growing and loyal customer base.

Product Categories

What is a Diamond Segment?

A diamond segment is a part of a circular saw blade or core drill bit that is coated with diamond grit, which is used for cutting through hard materials such as concrete, granite, and other natural and man-made stones. The diamond segment is usually made of metal with a layer of diamond particles that are held together by a bonding agent, and the size and shape of the segments depend on the type of saw blade or drill bit and the material being cut. As the blade or bit rotates, the diamond segments grind away at the material, creating a clean and precise cut.

High cutting efficiency

In the process of stone production and processing, cutting is a very important process. The choice of a good diamond segment should first be reflected in the efficiency. If the efficiency is low and the cutting speed is too slow, it will reduce the efficiency of producing stone, thereby increasing the cost.Therefore, the most important aspect of segmented cutting is efficiency. A segment without cutting efficiency is not a good segment.

Long cutting life

If the service life of the segment is longer, it can save the processing cost, such as welding cost, labor cost, saw blade replacement, inspection and other processes.Therefore, it is very important for the stone factory to cut more stone with the same efficiency.

The segment shape design is more reasonable

The shape of the segment is mainly used to increase the sharpness, increase the waterway and then increase the cooling effect of the coolant, facilitate chip removal, etc. A segment is a good diamond portion if the shape of the segment fulfills the above functions.

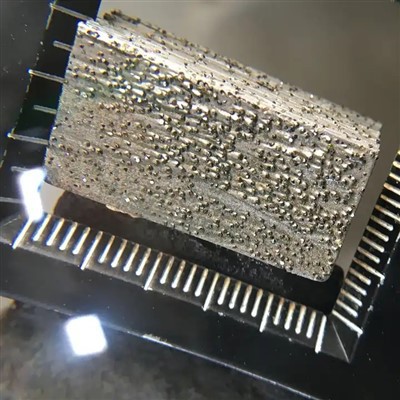

Surface diamond distribution

This characteristic is related to the efficiency of the segmentation, but the grinding speed is not only related to the cutting efficiency. In terms of rotational speed, if the grinding speed of the segment is fast, the saw blade can cut the stone well in the process of cutting the stone, and due to the high grinding speed, there will be no stone chipping and slate breakage.

Reasonable segment design

When we look closely at the diamond segment, we can see that this segment has obvious diamonds exposed on the surface of the segment, and there is a distinct trail behind it. Such segment structure design will make the quality of the segment more stable and the product sharper.

Efficient and Faster Cutting

The diamond segments are designed to provide an efficient and faster cutting speed. With their sharp edges and excellent hardness, they can cut through hard materials such as concrete, granite, and stone with ease.

Long-lasting durability

Diamond segments are made from high-quality diamond crystals that are extremely durable and can withstand high temperatures and pressure. They are designed to last longer than traditional cutting blades, reducing the need for frequent blade replacements.

Eco-friendly

Diamond segments are a greener option as they generate less waste and pollution during use. They are also recyclable, reducing environmental impact and improving sustainability.

Types of Diamond Segment

Straight Segment

This type of diamond segment has a simple design with a straight edge. It is commonly used for cutting soft materials such as marble, limestone and sandston

Sandwich Segment

This type of diamond segment has layers of diamond embedded in the metal matrix. It is suitable for cutting all kinds of materials, including hard stones such as granite and concrete.

Turbo Segment

This type of diamond segment has a series of holes or channels that help to increase cooling and reduce friction during cutting. It is ideal for fast cutting of hard materials.

Segmented Rim

This type of diamond segment has a segmented rim with a continuous rim that helps to reduce chipping during cutting. It is ideal for cutting abrasive materials such as asphalt, brick, and concrete.

V-Shaped Segment

This type of diamond segment has a V-shaped design that provides a smooth and precise cut. It is suitable for cutting hard materials like glass and ceramic.

Wavy Segment

This type of diamond segment has a wave-like design that helps to reduce vibrations during cutting. It is ideal for cutting hard materials such as reinforced concrete.

T-Segment

This type of diamond segment has a T-shaped design that allows for faster cutting of hard and abrasive materials.

Arrow Segment

This type of diamond segment has a unique arrow shape that provides a smooth and fast cut. It is great for cutting all types of materials, including granite, marble, and concrete.

Application of Diamond Segment

Used for mining saws for mining:Exploitation of mines, but people found that the mining efficiency of wire saws is not high, and is limited by site restrictions. The inability of multiple wire saws to be placed well becomes the biggest constraint on mining efficiency, in order to better improve Processing efficiency, people use mining saws to cut the mountains. The mining saws use large circular saw blades. Diamond segments are welded on these circular saw blades. The horizontal and vertical tracks are laid to complete the horizontal and vertical cross cutting. In the actual mining process of the mine, when multiple circular saws work at the same time, the mining efficiency of the mine is greatly improved. At present, this method is the most efficient method of mining.

Diamond segment is used for cutting blocks:For granite, granite blocks mined from mines need to be cut into stone slabs or smaller blocks, usually using sand saws, gantry cutting, combined cutting, etc. Machinery, these machinery will mount one or more circular saw blades, weld segments on these saw blades, and complete the cutting of blocks while the machinery rotates rapidly.

Diamond segment is used for cutting of plates:For 50mm thick plates, cutting into a certain specification of stone plates is a very important part of stone processing. Commonly used machines are hand cutting, hand cutting, and simple cutting machines. , Infrared bridge cutting machine and other machinery, diamond segment is welded on 300-450mm saw blade to complete the cutting of stone plates.

Diamond segment is used for grinding:Diamond segment can also be used for grinding stone, especially rough grinding parts, such as fixed thickness wheels, planetary grinding wheels, diamond grinding discs and other products, can be used to polish the granite surface through the diamond segment, and then cooperate Resin abrasives and polishing abrasives complete the polishing process of the stone surface.

Diamond segment is used for stone edge processing and shaping: At the construction site, due to the complex conditions, many panels processed from the factory need to be adjusted according to the site conditions, such as cutting and polishing, especially the corners. The cut panels have Sharp edges and corners are easy to scratch people. In order to make the stone smoother, it is necessary to use a diamond bowl mill (diamond segment is fixed on the bowl mill base by cold pressing or hot pressing sintering) to trim the stone.

Diamond drilling tools:There are many stone drilling tools, from mine drill bits to wash basin countertops, which are welded on drill bits with diamond segments. They are now very common, not only have an extremely long life, but also have extremely strong stability.

Material of Diamond Segment

01.Iron powder

02.Nickel powder

Tin powder: Tin powder is also the main material often used for granite segment.

03.Zinc powder

04.Copper powder

05.Diamond

Components of Diamond Segment

Diamond crystals:Diamond segments are made up of tiny diamond crystals that are embedded within a metal matrix. The diamond crystals are the primary cutting elements that help slice through the toughest materials, and they come in different shapes, sizes, and qualities.

Metal matrix:The metal matrix is the material that holds the diamond crystals in place. The metal can be a combination of various materials like copper, nickel, cobalt, and others. The type of metal matrix used depends on the type of material being cut, the desired cutting speed, and the diamond's quality.

Diamond concentration:The concentration of diamond crystals in the metal matrix is also an essential component of diamond segments. The concentration is measured in carats per cubic centimeter (CPC), and the higher the CPC, the more diamonds there are, which makes the blade more efficient.

Segment bond type:The segment bond type determines how the diamond crystals are held in place. There are various bond types, including electroplated, vacuum brazed, hot-pressed, and cold-pressed. The bond type used depends on the material being cut and the desired cutting speed.

Segment shape:The diamond segment's shape is also crucial, as it determines the blade's cutting performance. The segment's shape can be round, oval, rectangular, or twisted, and each shape serves a specific purpose. For instance, the twisted segment shape is ideal for cutting through reinforced concrete.

Segment pattern:The pattern of the diamond particles on the segment can affect the cutting performance and efficiency. Common patterns include continuous, turbo, and segmented.

Quality:Always consider the quality of the diamond segment. High-quality segments have better diamond concentration, appropriate bond type, optimized design, and are more durable. They cut faster and last longer, therefore, reducing the overall cost of cutting.

Material being cut

Consider the hardness and abrasiveness of the material to be cut. Harder and more abrasive materials require a diamond segment with a higher diamond concentration and a more durable bonding agent.

Saw specifications

Take into account the saw type, horsepower, and RPM to ensure that the diamond segment selected is compatible with your saw's specifications.

Cutting depth

Consider the depth of the cut required and select the diamond segment with the appropriate height to ensure a smooth cut.

Wet or dry cutting

Decide whether you will be cutting with water or dry and select a diamond segment that's appropriate for that cutting method.

Application

The application of the diamond segment matters. For example, some segments are intended for high precision cutting like glass while some are designed for flexibility in cutting, such as sandstone or granite.

Budget

Diamond segments are available with various diamond concentration, bond types, and quality levels at different prices. Consider your budget and select the diamond segment that offers the best long-term value for your money.

What You Should Know When Use Diamond Segment

Choose the Right Segment for the Job

Selecting the right diamond segment for the job is essential. The segment should be suitable for the material you are cutting or grinding.

Use an Appropriate RPM

Running your machine at the right RPM will not only improve your efficiency, but it will also help prevent diamond segments from wearing out prematurely.

Take Breaks

Diamond segments need to cool down to avoid overheating. Taking breaks during the process can prevent the segment from breaking or overheating.

Protect Yourself

Always wear proper safety equipment when using diamond segments, including safety glasses or goggles, ear protection, and work gloves.

Always Clean the Segment

After use, it is essential to clean the diamond segment. Soak it in a cleaning solution and gently brush it to remove any residue or debris.

Store Properly

Store the diamond segment in a dry, cool place to prevent moisture and humidity from damaging it.

How to Maintain Diamond Segment

Store the diamond segments properly:To prolong the life of your diamond segments, keep them in a dry and cool environment. Make sure to store them away from moisture and direct sunlight.

Clean after use:It is important to clean the diamond segments after use. Use a soft brush and a mild detergent to remove any debris and residue from the segments.

Use appropriate pressure:Avoid applying too much pressure on the diamond segments. Apply just enough pressure to get the job done, but not so much that it wears out the segments too quickly.

Use water:To keep the diamond segments from overheating, use water to keep them cool. This will also help to prevent any damage to the segments from excessive heat.

Use appropriate speeds:Depending on the type of machine being used, ensure that the diamond segments are being used at an appropriate speed. This will help to prevent any damage to the segments and prolong their life.

Replace worn segments:Once the diamond segments have worn down significantly, it is important to replace them with new ones. Continuing to use worn out diamond segments will only result in poor performance and a shorter lifespan.

Certifications

Our Factory

Our company has been committed to the international development in stone industry since its establishment 2016.All our abrasive products are made with quality materials and exceed ANSI and EU European Standards.We trust in delivering high-quality products to the end-user. Customer satisfaction is the lifeline of our quality.

Frequently Asked Questions Diamond Segment

As one of the leading diamond segment manufacturers and suppliers in China, we warmly welcome you to wholesale discount diamond segment made in China here from our factory. All our products are with high quality and competitive price.

tile cutting grinder wheel, tile cutting angle grinder disc, angle grinder blade for aluminum