Why Choose Us ?

Customized services

We understand that each customer has unique manufacturing needs. That's why we offer customization options, to cater to your specific requirements.

Advanced equipment

A machine, tool or instrument designed with advanced technology and functionality to perform highly specific tasks with greater precision, efficiency and reliability.

High quality

Our products are *manufactured* to very high standards, using the finest materials and manufacturing processe.

Competitive price

We offer a higher-quality product or service at an equivalent price. As a result, we have a growing and loyal customer base.

Product Categories

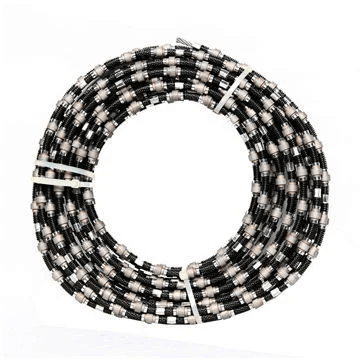

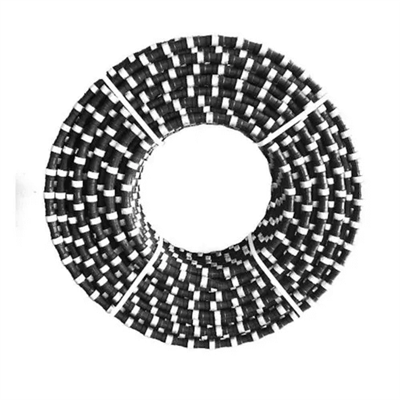

What is a Diamond Wire Saw?

A diamond wire saw is a cutting tool that uses a wire coated with diamond particles to cut through hard materials such as stone, concrete, metal, and glass. The diamond particles on the wire cut through the material through an abrasive action, allowing for precise cuts without the use of heat or pressure. Diamond wire saws are commonly used in construction, demolition, and mining industries.

Benefits of Diamond Wire Saw

Versatility

Diamond wire saw machines can cut through a wide range of materials, making them suitable for diverse applications in construction, mining, manufacturing, and more. They can be used to cut intricate shapes, large structures, and even thick materials.

Increased Safety

Diamond wire saws are designed with safety features to protect the operator during operation. The use of a wire instead of a solid blade reduces the risk of kickback, and the machine can be operated remotely, keeping the operator at a safe distance from the cutting area.

Precision and Accuracy

Diamond wire saws provide precise and accurate cutting, allowing for clean and smooth cuts. This makes them ideal for applications where precision is crucial, such as in the fabrication of intricate designs or when working with valuable materials.

Efficiency and Productivity

Diamond wire saw machines are often faster than traditional cutting methods, allowing for increased productivity and shorter project timelines. The continuous cutting action and ability to cut large sections at once can significantly improve efficiency in various applications.

Minimal Material Loss

Diamond wire saws produce thin cuts, resulting in minimal material loss compared to other cutting methods. This helps reduce waste and optimize material usage, making it cost-effective in the long run.

Reduced Vibration and Noise

Diamond wire saws operate with minimal vibration and noise levels compared to traditional cutting methods, which can improve the working environment and reduce operator fatigue.

Types of Diamond Wire Saw

Electroplated beaded wire saw:Electroplating wire saw is electroplating method of diamond plating fixed to the bead substrate, the benefits of this process is very obvious, the entire electroplating process does not need to be heated to complete the fixation of diamond powder, only the electroplating liquid constantly form a new diamond coating, so that diamond intact fixed in the plating layer. Since all the diamonds of this product are exposed to the outside of the wire saw, during the cutting process, the diamond layer of the diamond wire saw is mostly involved in the cutting process, so the efficiency of cutting will be greatly improved.

Vacuum Brazed bead wire saw:Brazing string beads is a vacuum brazing method, diamond powder fixed on the bead substrate of a process, and electroplating products similar, however, because the process used in this product is more environmentally friendly, will not be because of the larger pollution of electroplating liquid environmental protection eliminated, at present, electroplating products due to water pollution is larger, in a phased process, but brazing as a less polluted process, worry-free access to more people.

Sintered beaded wire saw:Sintered beads are diamond powder mixed with metal powder, and then sintered on the bead base, this structure of beads, diamond distribution is more uniform, the upper and lower layers can be cut, so the life of this product is very long, in terms of cutting capacity, this high wear resistance, can cut granite and other stone materials, and brazing and electroplating products due to consumption too fast, life is too short caused by high costs, is currently used in marble mining.

Application of Diamond Wire Saw

01.Marble mining wire saw

02.Granite mining wire saw

03.Plastic wire saw

04.Irregular-shaped wire saw

05.Combination wire saw

06.Reinforced concrete cutting wire saw

Metals:The material of diamond wire saw is a wire made of steel or other metals that are coated with diamond particles. The diamond particles are usually embedded in a metal matrix to form a continuous cutting surface. This type of wire saw is used in various industries, including construction, stone cutting, and semiconductor manufacturing. The diamond particles on the wire saw are the main contributor to its cutting efficiency, which is why diamond wire saws are commonly used for cutting hard and brittle materials such as stone, concrete, and glass.

Components of Diamond Wire Saw

Diamond Wire

The cutting element of the machine is a wire coated with industrial diamonds. Diamonds, one of the hardest materials, facilitate efficient cutting through tough substances like concrete and stone. The diamond wire is a crucial part responsible for the machine's precision and effectiveness.

Control Part

This component is integral for the operation of the diamond wire saw machine. It comprises driving functions, guiding functions, and walking functions. The control part ensures the wire moves along the desired cutting path with precision. The efficiency of this part is vital for achieving accurate and smooth cuts.

Machine Frame

The frame provides the structural support for the entire machine. It houses the components and ensures stability during operation. The frame needs to be robust to withstand the forces generated during the cutting process.

Power System

Diamond wire saw machines are typically powered by electric motors. The power system provides the necessary energy for driving the wire and other moving parts.

Cutting Head

The cutting head is the section of the machine where the diamond wire is attached. It accommodates various wire lengths and diameters, allowing flexibility in cutting different materials.

Tensioning System

To maintain the integrity of the diamond wire and ensure accurate cuts, a tensioning system is employed. This system keeps the wire appropriately tensioned throughout the cutting process.

Type of material being cut:Diamond wire saws are designed for cutting a variety of materials, including concrete, metal, stone, and glass. Different types of blades are required for different materials, so the specific material being cut should be considered before selecting a diamond wire saw.

Diameter and length of the wire: The diameter and length of the wire will determine the cutting depth and efficiency of the wire saw. Thicker wires are generally more durable and suited for cutting through harder materials, while thinner wires are more flexible and better suited for intricate cuts.

Price: Diamond wire saws can range in price from a few hundred to several thousand dollars, depending on the size and quality of the saw. It is important to consider the cost of the saw in relation to its intended use and the expected frequency of use.

Cutting speed

The cutting speed of the wire saw will determine how quickly the material can be cut. Faster cutting speeds are generally preferred, but may also result in a rougher cut.

Water usage

Diamond wire saws typically require the use of water to keep the blade cool and to reduce dust and debris. The amount of water required can vary depending on the type of material being cut, so it is important to consider the water usage when selecting a diamond wire saw.

Power source

Diamond wire saws can either be powered by electricity or hydraulic power. Electric saws are typically smaller and more portable, while hydraulic saws are more powerful and ideal for larger cutting applications.

What You Should Know When Use Diamond Wire Saw

Safety first:Always wear personal protective equipment such as gloves, safety goggles, and earplugs when operating a diamond wire saw.

Choose the right type of diamond wire:There are various types of diamond wires available, such as electroplated, vacuum-brazed, and sintered. Choose the type that's suitable for your task.

Check the wire tension:Make sure that the wire tension is appropriate before starting the cutting operation. Improper tension can cause the wire to break or create uneven cuts.

Keep the saw lubricated:Using water or cutting oil to lubricate the diamond wire will facilitate the cutting process and increase the lifespan of the wire.

Maintain a consistent speed:Keep a consistent speed while operating the diamond wire saw, as it can affect the wire's durability and the quality of the cut.

Conduct regular maintenance:Regular maintenance of the diamond wire saw will ensure proper function and increase its lifespan. Clean the saw and inspect the wire for damage or wear.

Properly store the saw:Always store the diamond wire saw in a dry and secure location to prevent damage and ensure safety.

How to Maintain Diamond Wire Saw

Cleaning:Regularly clean the wire saw to remove sawdust, debris, and other contaminants. Use compressed air or a soft-bristled brush to remove debris from the machine’s components, including the wire and the cutting head.

Tension:Keep the wire saw wire under proper tension. Use a tension gauge to ensure the wire is at the recommended tension level. Over-tensioning can cause the wire to snap.

Lubrication:Proper lubrication is essential to reduce friction and prolong the life of the wire saw. Use a diamond wire saw lubricant recommended by the manufacturer.

Water supply:The wire saw should have a consistent water supply to cool the wire and the blade. Ensure that the water is clean and free of debris to prevent damage to the saw and wire.

Alignment:The wire saw components including wire, drum, and support wheels, should be properly aligned. Misalignment can cause the wire to twist, leading to breakage.

Safety:Always follow safety guidelines when using the wire saw. Wear appropriate protective gear, follow recommended cutting speeds, avoid overloading the saw, and keep the work area clean and well-lit.

Maintenance:Conduct regular maintenance checks on the wire saw components, including bearings, pulleys, and cables. Identify any signs of wear and tear and replace the components immediately.

Certifications

Our Factory

Our company has been committed to the international development in stone industry since its establishment 2016.All our abrasive products are made with quality materials and exceed ANSI and EU European Standards.We trust in delivering high-quality products to the end-user. Customer satisfaction is the lifeline of our quality.

Frequently Asked Questions Diamond Wire Saw

Q: How does a diamond wire saw work?

Q: What is the cutting rate of diamond wire?

Q: How long does diamond wire last?

Q: Can a diamond wire saw cut steel?

Q: Can diamond wire cut wood?

Q: What is diamond wire made of?

The rope used on an industrial diamond wire saw machine is a made from a loop of high tensile steel connected by a mechanical joiner. On the outside of the rope are carrier rings, on which diamonds are either sintered or retained by an electroplated layer.

Q: What is a wire saw used for?

Q: What is diamond cut wire?

Q: Common Mistakes to Avoid When Using a Diamond Wire Saw

One of the most common mistakes people make when using a diamond wire saw is using the wrong type of saw for the job. Using the wrong type of saw can cause difficulties and can even be dangerous. A diamond cutting wire can either be a wet saw or a dry saw, and it is crucial to use the correct type for the job at hand. Wet saws use water as a lubricant and coolant, while dry saws do not use water. Therefore, one has to decide the right saw depending on the material to be cut, and whether water would damage the material.

2.Not properly adjusting the tension or speed of the wire:

Proper adjustment of the tension and speed of the wire is crucial. One must ensure that the wire is not too tight or too loose. If the wire is too tight, it is more likely to snap or break, and if it is too loose, it may cause the wire to drift from its intended course. Similarly, if the machine’s speed is not adjusted correctly, it can cause the wire to snap or put unnecessary strain on the wire. Therefore, it is important to adjust the tension and speed of the wire based on the material being cut.

3.Failing to lubricate the wire frequently enough:

Lubrication is critical when using a diamond wire saw. Using the saw without enough lubrication can cause excessive vibration, overheating, and can even damage the saw. Therefore, it is important to lubricate the wire often, especially when using a wet saw. Frequent lubrication helps the wire last longer and cut more precisely.

4.Pushing the saw too hard or cutting too quickly:

Pushing the saw too hard or cutting too quickly can cause the wire to break or snap. Additionally, it can also cause the machine to overheat, wear out too fast or cut inaccurately. Therefore, it is essential to use the saw within the recommended limits and to cut at a steady pace.

5.Not wearing appropriate safety gear:

It is important to remember that a diamond wire is a powerful tool and can be dangerous if not used correctly. Failing to wear appropriate safety gear, such as goggles, gloves, hearing protection or hard hats, can lead to severe injuries. When using a diamond wire saw, ensure that you are properly protected with adequate safety equipment before getting started.

Q: WHAT ARE THE BENEFITS OF USING A DIAMOND WIRE SAW?

Diamond wire sawing is popular because it cuts through most materials more quickly and efficiently than old cutting methods. It produces significantly less trash when compared to conventional teeth-like blades, which can save money in the long run.

Wire sawing is clean, fumeless, and quiet, with little to no vibrations, making it safe for sensitive work settings such as a hospital or school. The new machine is four to five times faster than traditional cutting processes, and it requires minimal human resources to run.

Q: What is a diamond wire saw?

Q: What materials can be cut with a diamond wire saw?

Q: How precise can a diamond wire saw cut?

Q: What safety precautions should be taken when using a diamond wire saw?

Q: Can a diamond wire saw be used in wet cutting?

Q: How long does the diamond wire last?

Q: What are the safety precautions when using a diamond wire saw?

Q: Can a diamond wire saw be used for underwater cutting?

Q: How do you select the right diamond wire saw for your cutting requirements?

Q: How do diamond tools work?

As one of the leading diamond wire saw manufacturers and suppliers in China, we warmly welcome you to wholesale discount diamond wire saw made in China here from our factory. All our products are with high quality and competitive price.

used diamond wire saw, cnc diamond wire saw, wire saw